Where a Revolving Surface is Required, Assure Stability With Lazy Susan Bearings

Whenever there are two machine parts that need to work together, without any friction between them, bearings are introduced into the system. Bearings support both radial and axial loads, depending on their design. There are various different designs, and all of them serve a different purpose and are made for a different type of machinery. Their name derives from the verb “to bear”, and they either restrict or allow different types of movements.

These small parts have been around for quite some time now, in one form or another, but the modern bearings, as we see them today, were designed by Philip Vaughan, an iron master and inventor in Carmarthen 1794. They played a crucial role in the Industrial Revolution, which allowed most of the newly-designed machinery to operate in a more efficient manner.

Some bearings enable linear movement in machines’ moving parts, other allow a free rotation around a fixed axis, while others prevent movement entirely by controlling the vectors of the moving forces that force the bearing on moving parts. Most bearing designs are used to improve motion by declining friction, and depending on the direction of the loads they apply, the motions they allow and the type of operation, they are broadly classified.

The most simple design of bearings are plain bearings, which feature a rotating shaft in a hole. They’re generally formed or cut into a part, and their form, control, size, roughness, location of form and surface can greatly vary. However, there are also plain bearings which aren’t cut or formed into the part, and act separately.

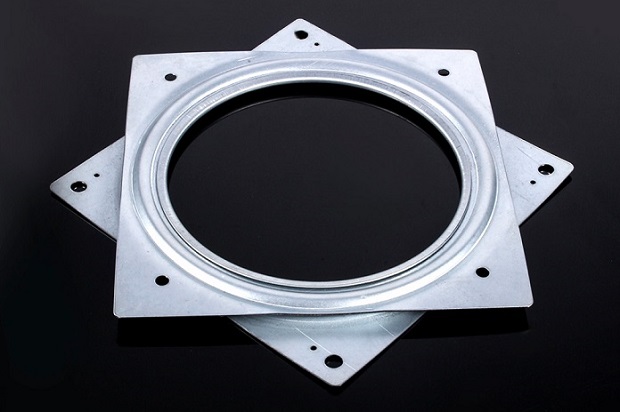

Moreover, there are much more complex bearings, like the lazy susan bearings (also known as rotary bearings), while predominately support axial loads. Lazy susan bearings are an ideal fit in low thrust applications, such as turntable kaleidoscopes, corner cabinets and storage solutions. Basically, whenever you need a stable, revolving surface, you’ll turn to these bearings. There are many more types of bearings which are used for specific applications and type of machinery. Those are typically made with high standards of reliability, durability and performance.

If you want to make the most out of the bearings, you should properly install them and lubricate them frequently. That way, the friction stays reduced to a minimum and you reduce the chance of abrasive and corrosive growths. However, not all bearings are high-maintenance. In fact, some require little to no maintenance whatsoever. It’s best you read the specifications on the bearings, and follow the recommended maintenance practices.