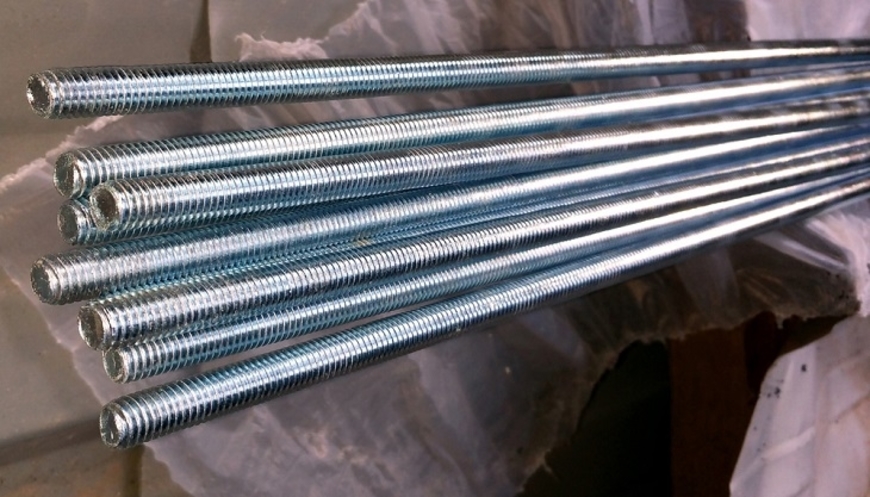

The Whats and The Hows of Threaded Rods

Fasteners come in all shapes and sizes, and differ in their application. Some are more versatile than others and can be used in different settings. Threaded rod or studs for instance find their way in construction, machinery, car engines, electrical installations, plumbing and a host of other fields. They are simple to use, easily formed and cheap to buy.

Contents

What is Threaded Rod?

A threaded rod is a common type of fastener. It goes by several names, like threaded studs, threaded bar or screw rods. It resembles long threaded headless bolts and screws, with the threading extending either along the whole length in what is known as all thread rod, or partially along both ends. It is used to fasten two items or materials together, and the long threading allows for high holding strength. Joints are further strengthened with the use of other fasteners, like bolts and nuts, and are easily added along with the threading.

Where is Threaded Rod Used?

A threaded rod can be used to permanently or temporarily fasten and join items of the same or different materials. The scope of use ranges from light to heavy-duty applications. For instance, in construction threaded bolts are used as structural supports in concrete anchoring, piping and plumbing, rail tracks, electrical poles and machinery. Threaded rod often finds its way in metalworking, the automotive and aviation industries in parts assembly, woodworking and furniture, various agricultural equipment and factory maintenance. Its demand in many fields is owed to how easy it is to work with, the good holding properties and that it provides for clean, neat finishes.

Materials in Threaded Rod

All thread rod and threaded rod variants are made of high-strength anti-corrosive metals. Here steel and stainless-steel rods are the most common. Galvanised and zinc plated rods are used in humid settings and best withstand corrosion. Brass is often found in smaller gauged rods, and in light ornamental uses and is recognisable by the distinct yellow colour. Aluminium and titanium rods are also sold, though are limited in usage. Other materials include plastic and nylon. These rods are found in precision equipment and parts assembly due to good resistance to high temperatures, friction and chemicals and are also lightweight.

Types of Threaded Rod

All Thread Rod

Also called thread bar, this is the most widespread type of threaded rod. As the name implies, the thread runs down the whole length so nuts and other fasteners can be installed at any point where needed. Most thread bar has right-hand threading and is positioned and tightened in clockwise turns.

Double Ended Threaded Rod

These fasteners have threading at either end in equal lengths and an unthreaded part in between. Variants with wrench flats in the unthreaded portion make them easier to install and tighten than an all thread rod.

Hollow Threaded Rod

These can be threaded either internally or externally and allow other rods to be easily connected. Hollow rods are mainly used in fixtures where cabling is routed in the inside, typically in lights. Differences in the spacing of the threading, or what is known as thread pitch, leads to a threaded rod with fine or coarse pitch. Rods with tightly packed threads offer higher tensile strength and grip better in applications where vibrations are common like automotive, machinery or aviation parts. Threading is mostly right-handed as mentioned above, but you can also source threaded rod with left-hand threading.

Sizing

Different types of threaded rods are available for your intended application. The benefits are that these start out particularly long, at 1000mm and can reach 3000mm. This allows for simple anchoring into masonry, or inversely cutting multiple pieces to the needed size from a single-threaded bar. Diameters start out at3mm and reach 50mm in longer rods. As bars increase in thickness, so does the thread pitch.

Using Threaded Rods

Since they come in longer and thicker than even the largest anchor bolts, threaded rods and all thread rod, in particular, is the preferred fastener in heavy-duty anchoring applications. They can also be cut to size, and a single rod will yield several pieces depending on the length needed. Cutting can be done with a threaded rod cutter to get the smoothest finishes, or with angle grinders or circular saws with compatible cutting discs. Cut pieces might need additional work to allow nuts to be fitted.

Rods are often installed with hand or powered torque tools, or drills. Tightening is done with a wrench or wrench tool. Several rods can be connected with threaded rod coupling nuts with internal threading in the appropriate diameter. Couplers also allow threaded rods of varying diameters to be joined, as well as a threaded rod with right-hand threading in one piece, and left-hand threading in another.

Benefits of Threaded Rods

Threaded rods are made of durable, corrosion and chemical resistant materials and are used in many applications. Variants with zinc plating are good for outdoor use and in settings with high exposure to liquids. Other materials provide a cleaner look and additional versatility. Rods are easily shaped, cut and installed with ordinary tools. They come in different lengths and diameters, and with couplers where jointing is required. And compared to other fasteners they are relatively cheaper. Threaded rods are sold in all well-stocked hardware stores nationwide.